January 2017 – May 2017

Academic Individual Project.

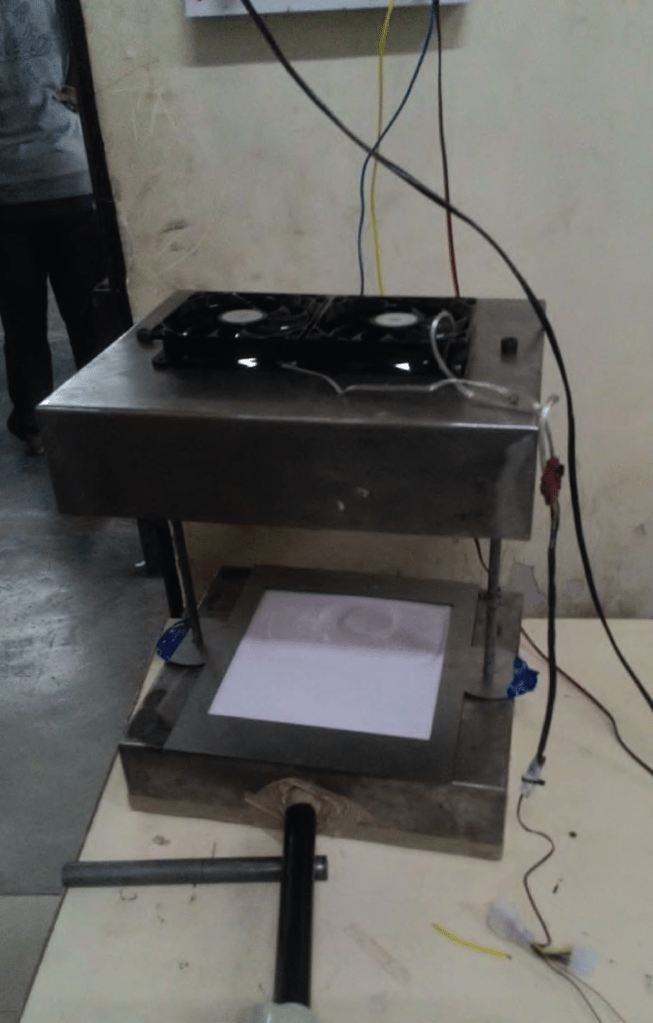

The vacuum former is able to build prototypes and parts efficiently, rapidly and at lower costs.

Gap in the market

Arya: She runs a bakery from home. She bakes cookies, cakes and

pastries also makes special chocolates in various shapes and sizes.

She needs moulds for chocolates, containers for pastries, and some

transparent cases for chocolate boxes.

As the demands fluctuates and orders are tailored for the customers and hence she needs customized moulds and casings.

Rekha: She is an architect and for her project presentations and

demonstrations she needs models of objects of multiple shapes and

sizes. She needs to design such models out plastic quickly.

Vedant: He runs a

mechanical workshop.

He often notices that small

objects such as tools, nuts

and bolts are not properly

kept and finds them lying

on ground mostt of the

time. It becomes difficult

to find all the parts from

a single tool box. So he needs containers and casings for numerous varieties of tools and parts which are specific to them for better storage.

Icons made by xnimrodx from www.flaticon.com

Problem Statement

In what way might I create a product so that making plastic parts and prototypes becomes inexpensive and less time consuming?

Identifying User Requirements

- 3D printing or injection moulding for prototyping or producing parts for low and medium quantity becomes time consuming and expensive.

- Outsourcing production such as injection moulding or even vacuum forming or thermoforming may not be viable if orders are customised.

- Small business cannot afford industrial vacuum former and a 3D printer.

- Existing vacuum formers are bulky and expensive.

- High Costs refrains creator from individually customizing and tailoring their products for their users needs.

Redefining Problem Statement

In what way might I create a vacuum former that:

- Has low initial as well as running cost,

- More affordable and accessible to people and makerspaces,

- Rapidly produces required parts and objects,

- Can be easily handled, maintained and stored.

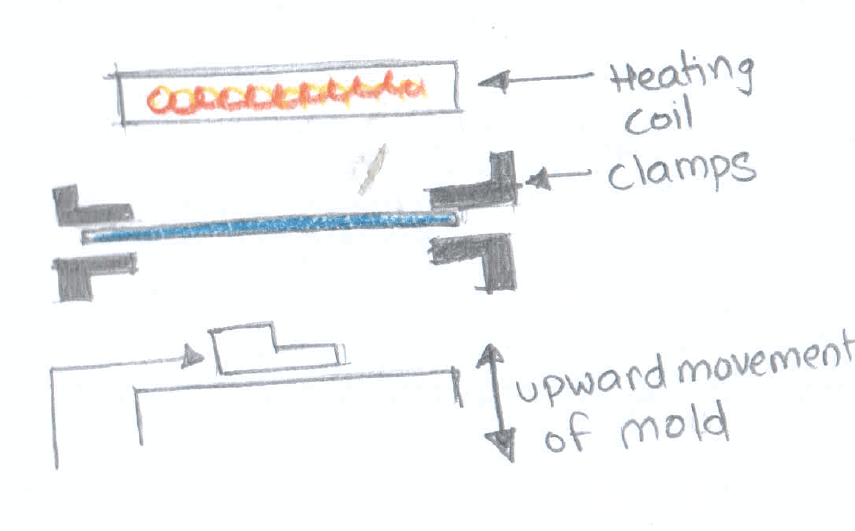

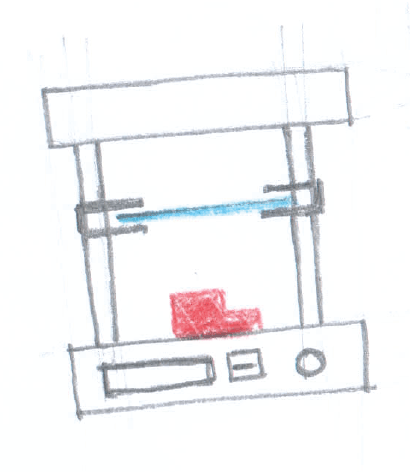

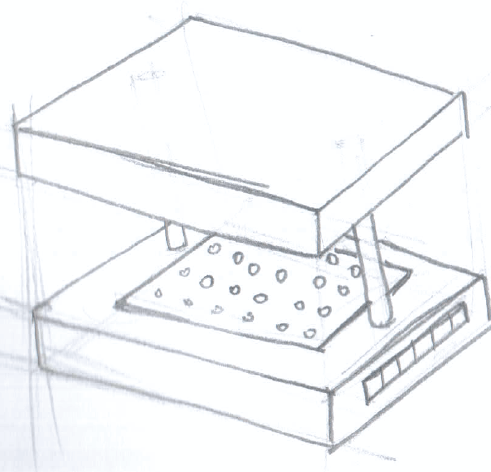

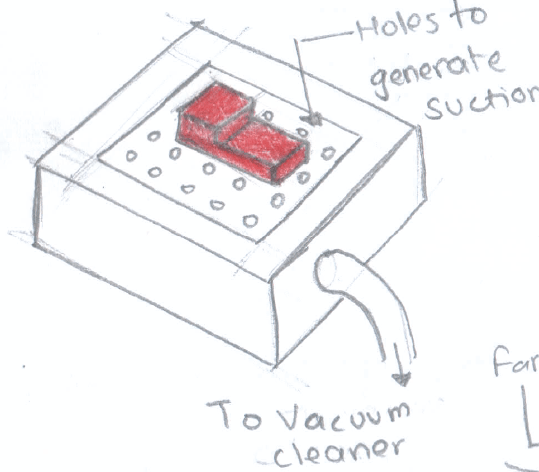

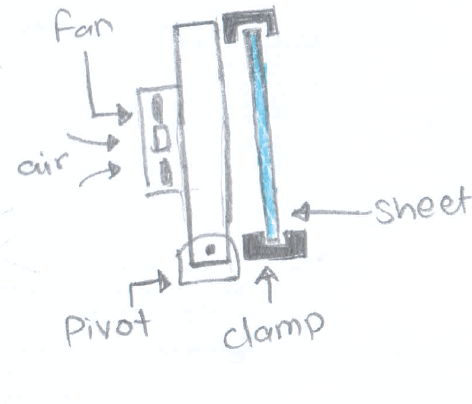

Brainstorming

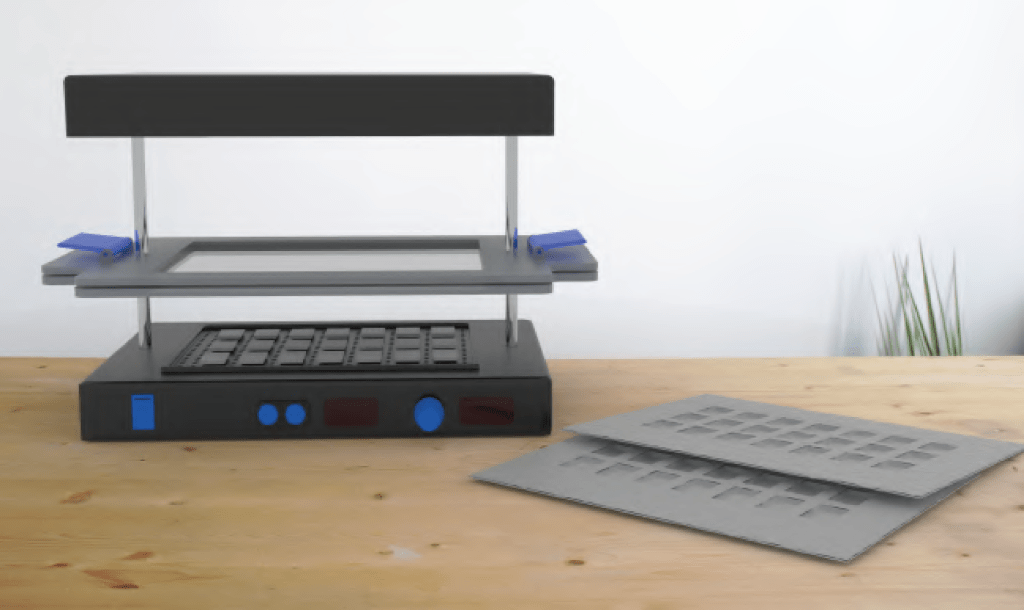

Parameters of Concept Selection

- Table Top Device

- Capable of producing multiple designs

- Capable of working with multiple materials

- Reduce production time

- Cost

- Easy to Use