July 2018 – February 2019

Professional Individual project

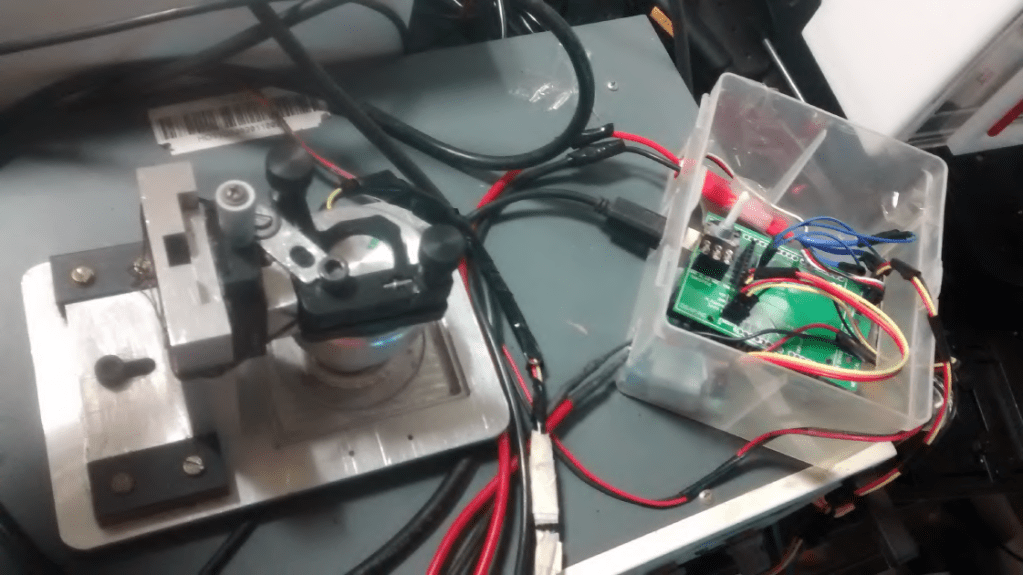

A microscope mountable fluid shear device for real-time imaging of cells and to quantify cell traction forces.

Design and Development

Fluid shear device is based on couette flow in which a cone is rotated above cells grown on substrate placed in Petri Dish containing biological media. The rotation of cone at certain speed produces shear force on cells causing them to de-adhere from substrate this shear force is to be measured.

I carried out the following work:

- Reducing vibrations of Petri Dish and Frame.

- Motor speed control.

- Reduction in compliance for accurate distance positioning.

- Developing real time control system to control and monitor temperature, humidity, and motor speed.

- Provision for accurate measurement of cone angle.

Reducing Vibrations and Compliance

Identification of cause of vibration and compliance

- The device has multiple joints and parts leading to tolerance stack-up.

- Unbalanced and unsupported mass.

Solution

- 3D printed clamps for petri dish.

- Rubber padding for frame.

- Reducing number of parts and joints by combining multiple parts and designing single multi-functional components.

Controlling motor speed

- Use of Infrared based tachometer.

- Development of calibration protocol for BLDC motor controlled with ESC using Arduino UNO.

- Developing calibration chart for speed vs voltage for speed control through voltage manipulation.

Environment Control

- Nichrome heating wire to control temperature.

- K-type thermocouple used to measure temperature.

- Humidity sensor to monitor humidity inside the chamber

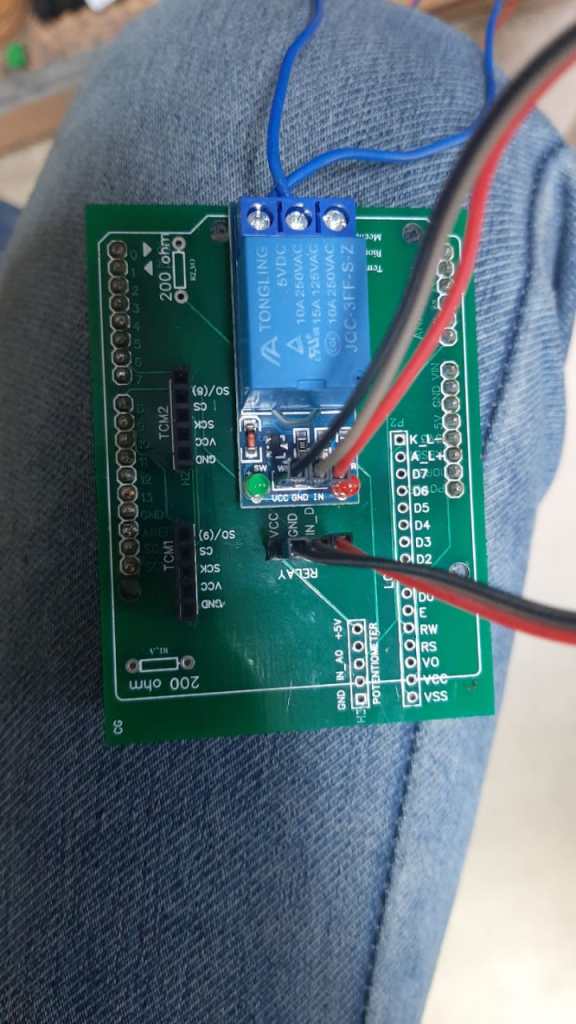

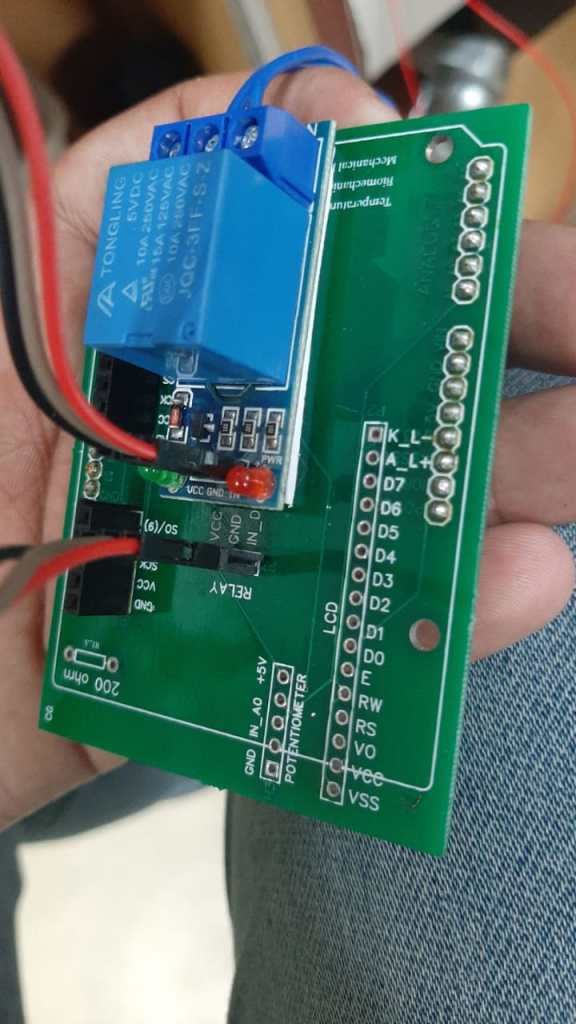

I designed the PCB using Eagle and EasyEDA software and assembled the components