February 2022– March 2022 (1 month)

Academic Project

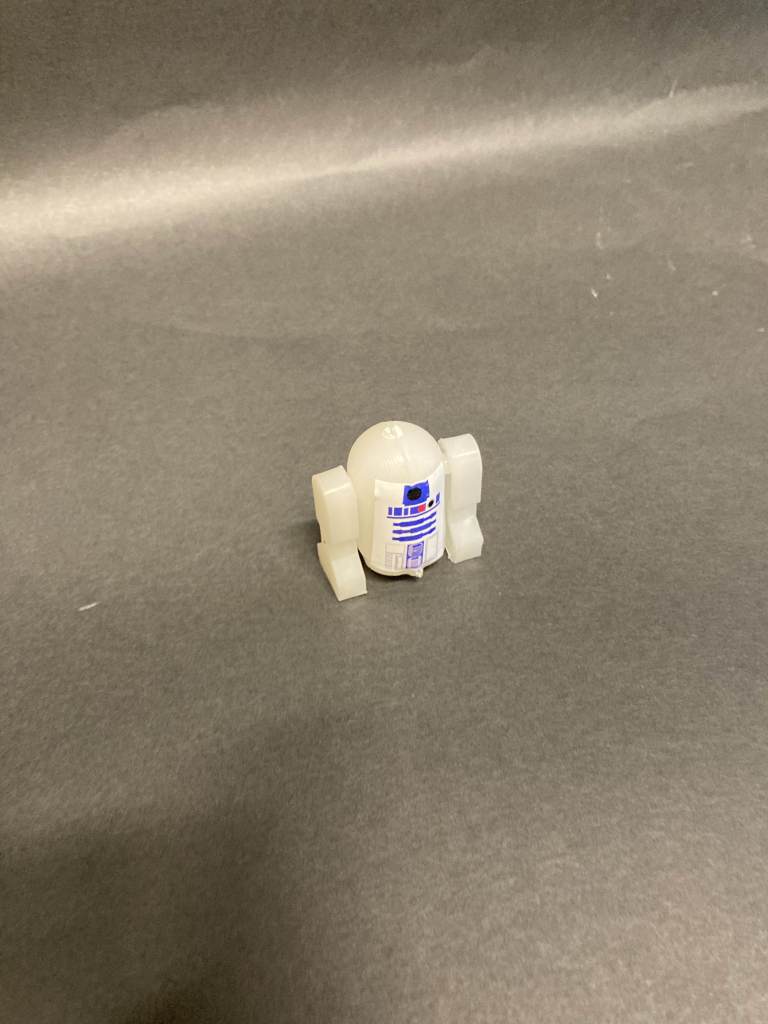

The aim of the project was to get hands on experience working with Morgan Press Injection Molding machine, 3 axis Hass mini mill CNC machine and MasterCAM. We designed R2D2 Action figure inspired from Star Wars.

The part was designed in SolidWorks and then using the MasterCAM module in Solidworks gcode file was created for milling the part from Aluminium Stock.

We performed draft analysis(we had 3° draft on all walls, holes and protrusions) on all the components, rearranged individual parts needed for assembly, simulated injection molding using SolidWorks Plastics for cooling time, ease of fill, max injection pressure, etc.

Main Learnings of the project were:

- Understanding Injection Molding process.

- Understanding guidelines and design consideration for injection molding process.

- Designing parts that can be injection molded.

- Performing draft analysis.

- Using Mold tools for generating molds.

- Understanding considerations for fixturing of stock for machining, Stock Preparation.

- Choosing right tools and toolpaths.

- Feeds and speeds.

- Tradeoffs between machining time, surface finish, accuracy and process time.