July 2018 – February 2019

Professional Individual project

Patent Pending – Application Number: 202041056145

Role: Lead Design and Manufacturing Engineer.

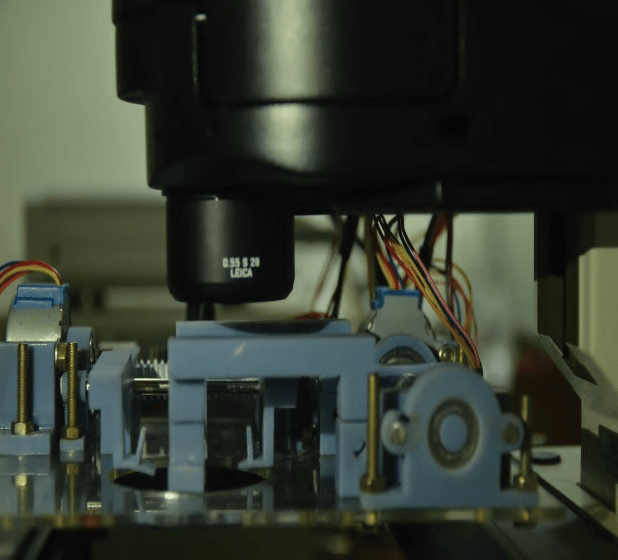

A microscope mountable non-equibiaxial stretcher for real-time imaging of cells and tissues.

Responsibilites

This project was part of my work at Biomechanics laboratory at the Indian Institute of Science.

- Work with a colleague from Biosystems and Bioengineering Department, with a background in Material Science and Cell Mechanics on the required product specifications.

- Come up with different drive mechanisms.

- Prototyping and testing the design for spatial and functional constraints

- Connect with vendors and suppliers to build the product to required specifications.

Due to confidential nature of this work entire details cannot be mentioned

Project Sponsors

Motivation

Why there is a need of microscope mountable Biaxial Stretcher?

- Measurement of forces and microstructural changes during deformation are both critical to our understanding of tissue biomechanics.

- Visualization of microstructural constituents during tissue stretching is often challenging due to hierarchical organization of different proteins and cells.

- Mechanobiological studies at cellular levels are essential to explore form and function in tissues.

- Biaxial/uniaxial experiments, with amplitude/ frequency control, in two orthogonal directions are required.

Drawbacks of Existing Devices

Exhaustive search for commercially available cell stretchers and those developed by other research labs was done. Following drawbacks were noted

- Real-time imaging was not possible due to size and shape of the other stretchers.

- Inability to image on inverted microscope.

- No load cell ( required for quantifying stresses ).

- Huge media consumption. ( expensive )

- Inability to focus on the stretching region.

Brainstorming

We conceptualized and identified various ways (mechanisms, actuators, placement of devices, power sources, etc.) that can be used to stretch biological cells and elastomeric substrates.

Prioritizing our needs really helped to shortlist the final ideas that we tested by building low fidelity prototypes. Different prototypes were build to tested different aspects of the design, such as linear actuator mechanisms, clamps, materials, shapes, vibrations, placement of components, etc.

Design and Development

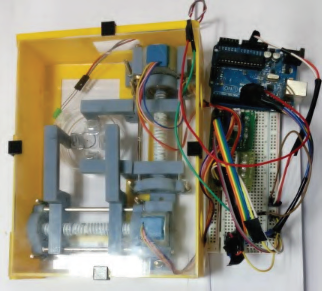

Initially a prototype was developed, which was 3D printed. The motors were controlled by Arduino UNO and motor drivers.

The prototype was helpful in getting inputs on

- Size estimation.

- Concept proof.

- Placement of parts.

- Objectives.

Development of Biaxial stretcher

We have a completely ready setup(hardware and software) that is currently being used in Biomechanics lab at IISc to perform experiments.

IISc and a hardware company(cannot disclose the name here) based in Bangalore, KA are signing a licensing agreement to take over the device for further commercialization.

I cannot disclose exact design of the device here, but feel free to contact me. We can always chat!